Crimping, Wire Wrapping and Wire Soldering to ESA Specifications ECSS-Q-ST-70-26, ECSS-Q-ST-70-30 and Wiring to ECSS-Q-ST-70-61

E09 [will be discontinued in 2025]

This ESA-approved course will review the latest revisions of the ECSS-Q-ST-70-26, ECSS-Q-ST-70-30 and a restricted (to the wiring sections only) ECSS-Q-ST-70-61 standard and is followed by open book multiple-choice tests. The review of the standards will give an understanding of the contents of the specifications and why they are important. The test is designed to develop your ability to navigate the standards and find relevant information in an efficient manner.

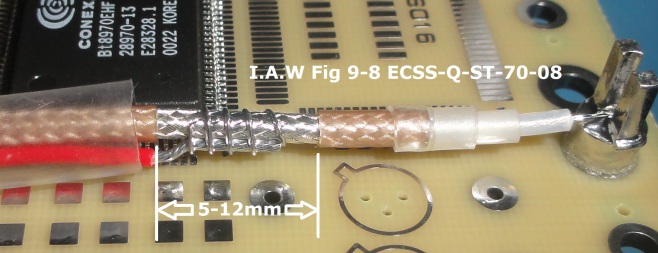

The requirements in the standards are designed to ensure process consistency and acceptable workmanship standards resulting in the production of “The Crimping of High-Reliability Electrical Connections" ECCS-Q-ST-70-26, "The Wire Wrapping of High-Reliability Electrical Connections", ECCS-Q-ST-70-30, plus the content of ECSS-Q-ST-70-08 that relates to soldering and wiring to connectors and terminals.

The course also has a practical test. For inspectors, the practical will be the QA inspection of others’ Crimping, Wiring and attachment of wires to terminals and connectors on a PCB. For operators, the practical consists of crimping wires and destructive testing, attaching wires to terminals and destructive testing and hand soldering wires to connectors and terminals on a PCB in accordance with the standard. Results are also inspected by the instructor to ensure an understanding and an acceptable level of practical skills can be demonstrated in accordance with the standard.

All necessary tools and equipment are supplied, although delegates are welcome to bring their own hand tools if desired.

Course aims

- To review and understand the requirements of the specifications;

- To identify the factors which influence the quality, reliability and performance of crimped or wire-wrapped connections and soldered wiring;

- To develop correct assembly and testing methods;

- To develop the ability to identify and analyse associated faults.

Course content

- Theory of solderless connection methods

- Knowledge of critical parameters affecting the quality and function of connections

- Advantages and disadvantages of compared with soldering

- Soldering to wires and terminals

- Routing and lacing of wire bundles* chafe prevention

- Tool selection

- Tool adjustment and quality control

- Processing crimp and wrap surveys

- Recognising range of crimp formats

- Correct wire preparation

- Correct terminal preparation

- Tensile testing sample connections

- The importance of cleanliness

- Recognition of faults.

Award

In accordance with ESA STR-258, an ESA approved, Category 3 Certificate, valid for 2 years, will be awarded on successful completion of the course for operators and a Category 2 Certificate, valid for 2 years will be awarded on successful completion for inspectors.

Experience and pre-requisites

- Minimum of one year of industrial soldering (soldering wires to connectors and terminals) and wiring experience, verified by the employer / manager

- Familiarity with electronic wiring and assembly processes

- Good practical skills

- A positive attitude to high quality workmanship

Duration, schedule and fees

5 days – Please see the current Course Calendar for dates and fees.

Recertification

To renew certification for a further 2 years, a 4-day total duration recertification courses E96+ and E97 are available.